China has its own in-house design for a hydrogen fuel cell now.

When it comes to new energy vehicle technologies, battery electric vehicles are not the only way forward. Many still believe that hydrogen fuel cell power is more viable. For that reason, many brands have continued to push fuel cell technology forward with new innovations and patents. South Korea and Japan both seem to have the largest advantage in this sector. Now, China’s SAIC Motor has its very own fuel cell technology to tinker with called the PROME P4H fuel cell system.

SAIC’s hydrogen power was developed by their subsidiary, Shanghai Hydrogen Propulsion Technology Co., Ltd. They launched their family of fuel cell systems on the 28th of October 2021, marking the first major breakthrough by a Chinese company in fuel cell energy technology.

The development is being pushed by the Chinese government, which has set a goal of achieving carbon neutrality by 2060. Not only is SAIC Motor the first automaker in China to develop fuel cell tech, but it also claims to be the first company in the world to have achieved commercial application of multiple fuel cell vehicles. The company has unveiled and launched a number of fuel cell cars, MPVs, light buses, coaches, and trucks that now operate in 13 Chinese cities.

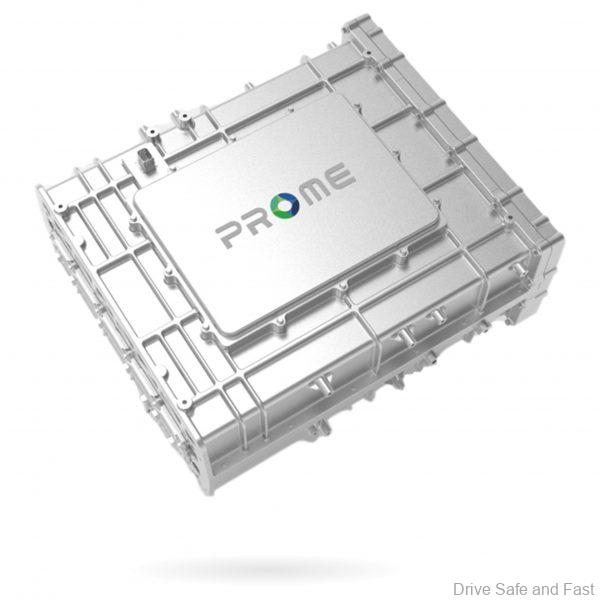

Shanghai Hydrogen Propulsion Technology is capable of developing all the core components of fuel cell stacks, integrating stacks, fuel cells and fuel cell propulsion systems in-house. They independently own the intellectual property for all of these elements as well. The 44 primary components of the Prome M4H fuel cell are all designed and developed domestically and they claim it’s of the same world-leading standard as those made by Toyota.

However, they also say that their design is smaller and more powerful with a volumetric power density of 1020 W/L and mass power density of 722 W/kg. The system is also capable of withstanding shocks and vibrations expected in a vehicle and has an IP67 dust and water resistance level.

The fuel cell stack platform can be configured for power ranges between 30 kW and 230 kW. The company says they can produce 4,000 units by the end of 2022.