Are electric vehicles good for the environment?

The automotive industry has committed to making the transition to electric vehicles, or at least electrified vehicles for most regions within the next 1-3 decades. Some brands, like Genesis and DS have gone all out, promising to transition to pure EVs soon. Other carmakers like Mercedes-Benz and Volvo Cars have shown a similar intention. The reason given usually pertains to climate change and the emissions that the internal combustion engine produces is usually the target of this.

Electric vehicles don’t have tailpipe emissions. That much we know is true. But that’s not the whole story. We know that many countries around the world, including Malaysia, use coal to generate power for the grid. Are we simply shifting the emissions of petrol to a much worse source of carbon emissions?

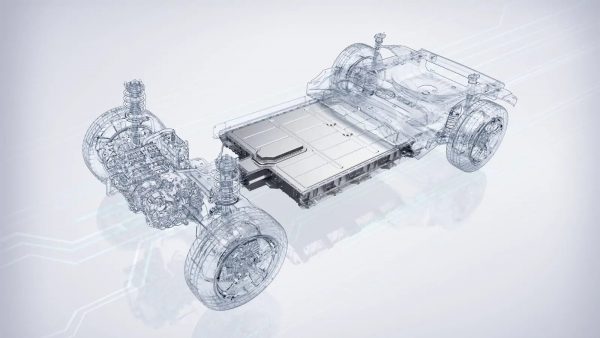

We also know key ingredients in most car batteries include cobalt and lithium. Not only are these materials extremely expensive (US$15,000-US$27,000 per tonne vs US$74 per tonne for iron) but harvesting them is also bad for the environment. These materials and other rare-earth elements that go into batteries produce radioactive residue according to the Chinese Society of Rare Earths.

What’s more, the energy used to extract these elements and produce batteries is . Nearly half the environmental impact of electric cars somes from battery production itself.

So, are electric vehicles worse for the environment than petrol or diesel alternatives? Well, not really. Studies have shown that even with the current ‘dirty’ electrical grid that we have, an electric vehicle will offset its emissions after being driven for 2 years. So, in the first two years of its life, it’s actually polluted more than an equally old petrol vehicle. But after that, it gets greener.

What does that mean? Well, it means that if car manufacturers are going to take electric vehicles seriously for environmental reasons, then they have to make sure their vehicles are viable for customers to run for a long period of time. Typically, the industry measure a vehicle’s lifespan as about 5 years. This ought to extend further and the best way to do this is to make servicing electric vehicles easy and replacing parts straightforward and open. Locking the car to only OEM parts will undoubtably lower the lifespan of the vehicle, but of course that’s the trajectory we’re heading down.

Carmakers also need to embrace the philosophy of allowing parts to be remanufactured and repaired instead of being replaced and recycled. We know that recycling, though good for the enviroment, is not a perfect solution. Many materials are difficult to recycle and often not worth recycling. Designing car parts to be easily fixed instead would doubtless string along other environmental benefits. Carmakers also have to track batteries more effectively to ensure they can be reused instead of disposed of when they’re older.