As electric vehicles mature in the Chinese market, the country’s EV battery Recycling Industry has been booming.

While electric vehicles are not yet the norm, for about half a decade, many parts of the world have embraced ‘New Energy Vehicles’ (NEV) of all sorts. Many of these NEVs have become obsolete or have been retired for other reasons. In China, batteries from these retired NEVs are being recycled en masse and an entire ecosystem and industry has spawned to cater to the demand and supply aspects.

Just How Much Has The EV Battery Industry Grown In China?

China’s EV Battery recycling industry has grown from 2.9 GWh to 21.2 GWh in a matter of 3 years, equating to a compound annual growth rate of 78.5%. In 2020 alone, 200,000 metric tonnes EV batteries were retired in China. By 2025, this number is expected to climb to about 780,000 tonnes.

Currently, over 15,000 companies in China are engaged in EV battery recycling activities with over 9,000 being newly registered this year. As PHEVs gain popularity expand in Malaysia, perhaps we too should look at EV battery recycling.

Why Is EV Battery Recycling Important?

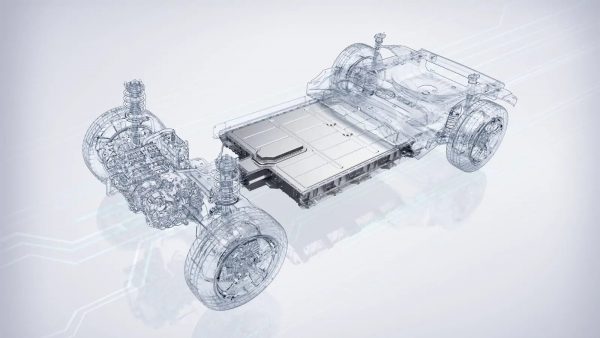

The materials that go into EV batteries are expensive to mine and quite valuable. By recycling these batteries, manufacturers get a secondary supply of raw materials. What’s more, since NEVs are tied to the idea of reducing pollution, it works quite well that recycling batteries reduces the pollution caused by both the improper disposal of batteries and the energy that goes into harvesting these materials raw from the earth.

How Are China Making It Work?

EV battery recycling is not as straightforward as one might think. The amount of effort that goes into coordinating and encouraging the industry to grow has been quite immense. It started with a written notice by the National Development and Reform Commission on its development plan of the circular economy during China’s 14th Five-Year Plan for 2021-2025. The government announced that they would make it so that EV battery tracking was mandated for manufacturers.

From there, other government instruments were released to encourage cooperation between NEV manufacturers, power battery producers and recycling companies. At a lower level, local governments began to promote EV battery recycling in their own provinces. In Jiangsu, for instance, 907 EV battery recycling centres have been deployed. Shanghai has full life cycle tracking for EV batteries already set up.

What Are The Difficulties In EV Battery Recycling?

Despite the growth of this industry in China, there are still problems such as:

- irregular recycling methods

- low recycling and utilisation rates

- safety issues

- high recycling costs

- difficulties in material seperation

How Is EV Battery Recycling Done?

There are two main ways. Cascade Utilisation and Material Separation.

Cascade Utilisation takes batteries that have fallen below the 80% capacity and test them for suitability in other fields. Stationary power banks for cities is one. This method is quite common, and 87% of recycled batteries go through cascade utilisation. However, it’s still tough to test the quality of these batteries evaluate their reliability and performance accurately.

For batteries that are below 30% capacity of their original spec, these go through a more labour intensive process of stripping them and seperating materials for recycling.

This article was adapted from information found on chinadaily.cn